Contact Us:

0551-65817158

中文

中文

Contact Us:

0551-65817158

中文

中文

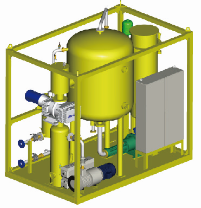

Main Application

Evacuation of electrical equipment such as power transformer and electric reactor;

Filling of the vacuum equipment with oil;

Generating of hot oil circulation in these machines.

Technical Features

Heat Transfer Way: Adopt heat-exchange model,in which heat the media firstly, then enable it to exchange heat with the oil of transformer in plate heat exchanger. Such technology helps avoid oil breaking caused by heat aggregation due to sudden power outage, moreover improve both temperature rise and power energy efficiency. This method remains safer, more efficient and energy-saving(saving 30% electric energy).

Degassing Way: Use a improved single degassing tank, which can remove the gas and moisture from transformer's oil completely. Vacuum Pipes are equipped with high-performance condensers and oil-gas separators to get the facility kept in functional order.

Filtering: Use newly and precisely customized filter cartridges. With big dirt receiving capacity, this filter cartridges remove solid particles from oil more thoroughly to meet requirements of ±1100KV direct current transformers.

Electric Control: Siemens PLC has been applied to control equipment in a remote, wireless and unmanned way.

Else: Amid processed precisely and adopting international famous brands, machinery and electric parts possess high quality, guaranteeing the fixed running costs of the equipment.

Type Introduction

Technical data of Vacuum Oil Treatment

Note: Above data is fit for the oil of new naphthenic base transformer. May reset vacuum oil

treatment 's parameters according to clients' actual needs.